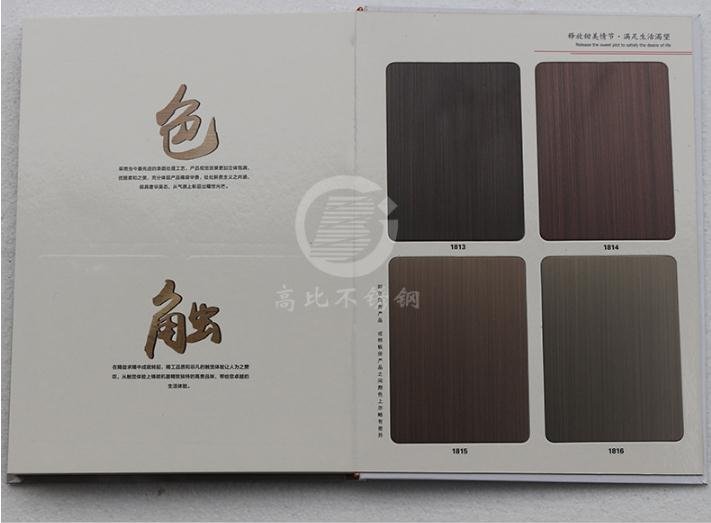

High specific stainless steel sample book for copper plating

Model No.︰H-0001镀铜样板册

Brand Name︰Foshan Gaobi

Country of Origin︰China

Unit Price︰CNY ¥ 300 / pc

Minimum Order︰1 pc

Product Description

Cyanide copper plating is the earliest and most widely used copper plating process. The plating bath is mainly composed of copper cyanide complex and a certain amount of free cyanide, which is strongly alkaline. The first characteristic of this electroplating method is that the solution has certain deoiling and activating ability because of the strong activation and complexing ability of cyanide root. Secondly, because this plating solution used a strong complex of cyanide, so that the complex ion discharge is not easy, so that the bath cathodic polarization is very high, with excellent uniform plating capacity and covering capacity. The color surface generally has the red copper, the brass, the bronze, if in these three colors in addition to the drawing process will produce the red bronze, the bronze, the brass these three different colors. Widely used in high-end leisure venues, Star hotels, luxury counters, luxury doors. For various body and coating requirements, with a different special "water plating" solution, was plated parts at room temperature (15 ~ 40 °C) , placed in the water plating solution, for a slight shake, in a shorter time (such as silver plating, only 30 seconds) can be completed. CHARACTERISTICS OF WATER PLATING PROCESS: 1. Without heat source, the coatings are deposited at 15 °C or 40 °C. 2. The principle is not to cover, but to make the coating and the base material combined to form an alloy, its bonding strength greatly increased it is worth noting that: 201 # water plating black titanium better than electroplating, electroplating gray 304 # water plating, black titanium, black with blue and electroplating gray-black single effect on the appearance of water-plated and wear resistance is better, but water-plated pollution. Vacuum plating has low cost, no pollution and high production efficiency.

Payment Terms︰ Bank transfer

Product Image